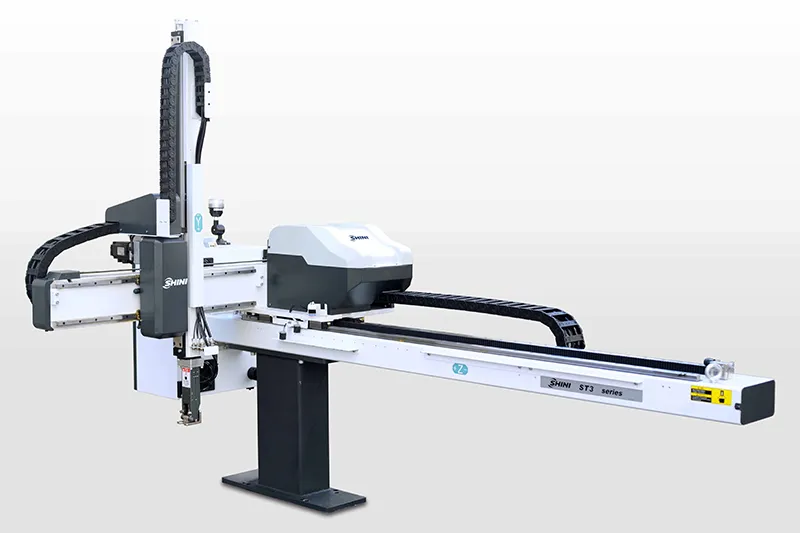

Five-Axis Servo Driven Robot

Traverse robot used in plastic injection molding process to remove sprues and products

The five-axis servo driven robot is an enhanced solution in plastic processing automation, specifically designed to increase efficiency in injection molding operations. It is equipped with servo motors on all five axes, ensuring high-speed operation, precision, and low noise.

The five-axis servo driven robot is an enhanced solution in plastic processing automation, specifically designed to increase efficiency in injection molding operations. It is equipped with servo motors on all five axes, ensuring high-speed operation, precision, and low noise.

- Utilizes high-precision linear rails and imported high power V belts for fast and accurate positioning, with a double-section arm design that doubles the speed and stability of movements.

- Features collision protection at all movement extremes and dual software and hardware safety protections to ensure operational safety and prevent circuit damage due to external electrical shorts.

- Equipped with a 7-inch TFT high-definition touchscreen that offers a friendly user interface, USB connectivity for upgrades of remote controllers and motherboard, as well as program downloads, open teaching functionality, 8GB of storage, and the ability to expand up to four additional 16-bit I/O boards.

- RS-422 ports to enhance system response times and ensure maximum safety.

- The hardware uses a multi-layer PCB structure and multi-stage high-precision power modules, enhancing its interference resistance.

This series of five-axis servo driven robot is designed to accommodate a variety of mold types, including two-plate, three-plate, and hot runner molds, with the flexibility of single or telescopic arm configurations. It is capable of performing specialized tasks required in modern plastic injection molding facilities. Ideal for tasks such as the removal of finished products and runners, it supports a range of complex actions like arranging, stacking, and quality inspection, suitable for use with injection molding machines up to 850 tons.

| Robot type | ||||

| IMM (ton) | 220-260 | 320-400 | 450-650 | |

| Traverse stroke (mm) | 1600 | 1800 | 2000 | |

| Crosswise stroke (mm) | Main arm | 420 | 650 | 750 |

| Sub arm | 420 | 650 | 750 | |

| Vertical stroke (mm) | Main arm | 900(1000 | 1100(1200) | 1300 |

| Sub arm | 950(1050 | 1100(1200 | 1300 | |

| Max. load (with tool) (kg) | 5 | 6 | 6 | |

| Min. pick-out time (sec) | 1.3 | 1.5 | 1.5 | |

| Min. cycle time (sec) | 5.5 | 6.2 | 6.5 | |

| Air pressure (bar) | 4~6 | 4~6 | 4~6 | |

| Max. air consumption (Nl/cycle)* | 5 | 5 | 6 | |

| Weight (kg) | 310 | 340 | 370 | |

| Dimensions (mm) | A | 2760 | 3010 | 3210 |

| B | 1490 | 1710 | 1710 | |

| C | 1300(1350 | 1490(1540) | 1610 | |

| D | 900(1000 | 1100(1200 | 1300 | |

| E | 950(1050 | 1100(1200) | 1300 | |

| F | 1600 | 1800 | 2000 | |

| G | 145 | 160 | 160 | |

| H | 140 | 160 | 160 | |

| I | 700 | 1030 | 1030 | |

| J | 240 | 240 | 240 | |

| K | 175 | 240 | 240 | |

| L | 2020 | 2150 | 2350 | |

| Notes: 1) "M" stands for middle mold detector (suitable for 3-plate mold) "EM12" stands for Euromap12 communication interface "EM67" stands for Euromap67 communication interface "N" stands for non-operation side 2) Power: 1φ, 200-240V, 50/60Hz 3) "*" stands for extra 60Nl/min of air consumption for vacuum application 4) "( )" stands for optional | We reserve the right to change specifications without prior notice. | |||

| Model | ST5-1500-2200DT-S | ||

| Robot type | Frame type beam | ||

| IMM (ton) | 650-850 | ||

| Traverse stroke (mm) | 2200 | ||

| Crosswise stroke (mm) | Main arm | 850 | |

| Sub arm | 850 | ||

| Vertical stroke (mm) | Main arm | 1500 | |

| Sub arm | 1550 | ||

| Max. load (with tool) (kg) | 12 | ||

| Min. pick-out time (sec) | 3.5 | ||

| Min. cycle time (sec) | 9.5 | ||

| Air pressure (bar) | 4-6 | ||

| Max. air consumption (Nl/cycle)* | 6 | ||

| Integrated control unit and drive | - | ||

| Weight (kg) | 930 | ||

| Dimensions (mm) | A | 3850 | |

| B | 2140 | ||

| C | 1610 | ||

| D(max) | 1500 | ||

| E(max) | 1550 | ||

| F(max) | 2200 | ||

| G(min) | 245 | ||

| H(min) | 170 | ||

| 1(max | 1220 | ||

| J | 2900 | ||

| Notes: 1) "M" stands for middle mold detector (suitable for 3-plate mold) "EM12*" stands for Euromap12 communication interface "EM67" stands for Euromap67 communication interface "N" stands for non-operation side 2) Power: 1φ, 200-240V, 50/60Hz 3) "*" stands for extra 60Nl/min of air consumption for vacuum application 4) "( )" stands for optional 5) "●" stands for optional, and add "I" in the model code, and "-" means unavailable | We reserve the right to change specifications without prior notice. | ||

With over 55 years of manufacturing experience, we are an experienced manufacturer of plastic auxiliary equipment, now serving clients in more than 80 countries and regions worldwide. Our extensive service network ensures we deliver exceptional support wherever our customers operate.

- Ensure the long-term reliability of your equipment.

- Boost production efficiency and reduce operational costs.

- One of our core commitments is to provide readily available spare parts and accessories, significantly extending the life of your plastic production lines.