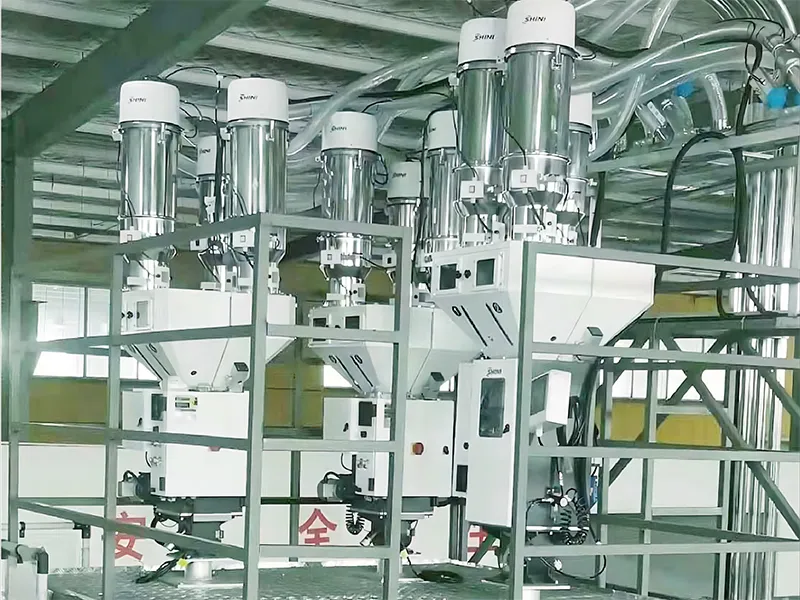

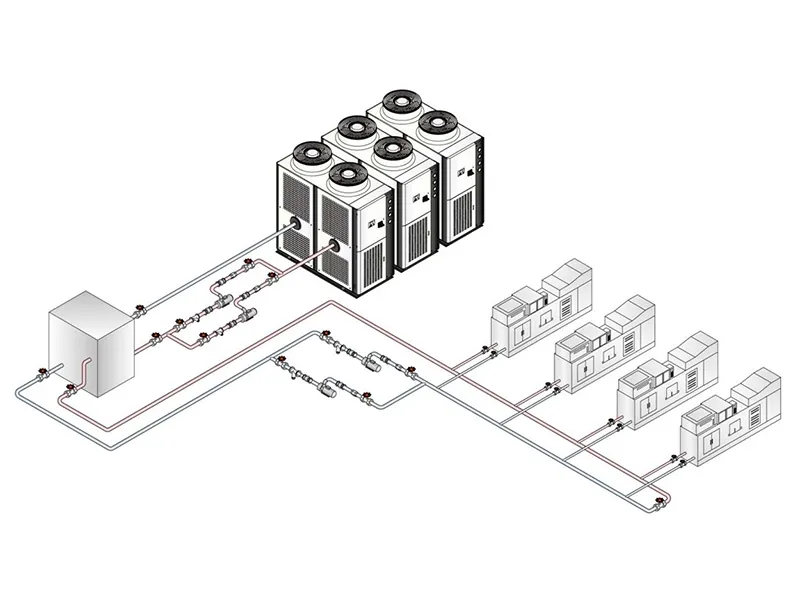

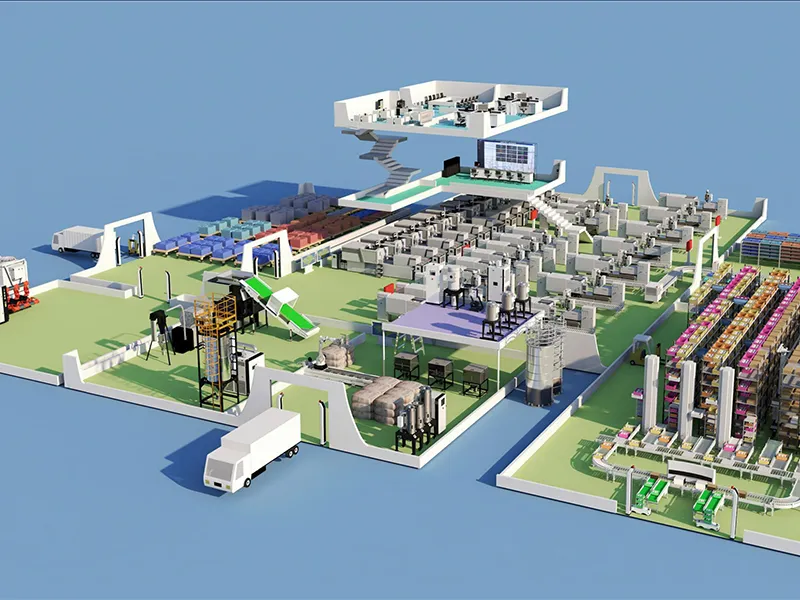

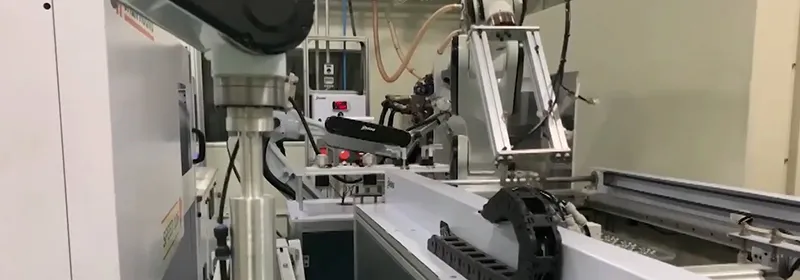

The industry 4.0 smart factory solution integrates the monitoring of essential auxiliary devices like gravimetric blenders, chillers, and mould temperature controllers directly through the control system of injection molding machines.

By employing an Ethernet connection, this unified system enables monitoring and management of all connected equipment from the injection molding machine's interface. This seamless integration significantly boosts efficiency and improves equipment management by providing a real-time overview of the entire manufacturing process.

- The production platform is versatile and quick to adapt, ensuring it can be integrated into any injection molding process easily

- Offers a comprehensive, interconnected setup that facilitates smooth communication between the manufacturing operations and enterprise resource planning systems, enhancing workflow and data transparency

- Smart monitoring capabilities utilize visual data to provide important performance indicators, simplifying the management of manufacturing processes through intuitive user interfaces

- Features innovative process management that supports all aspects of production, from planning and execution to maintenance and quality control, now with enhanced content versioning capabilities for better process documentation

With over 55 years of manufacturing experience, we are an experienced manufacturer of plastic auxiliary equipment, now serving clients in more than 80 countries and regions worldwide. Our extensive service network ensures we deliver exceptional support wherever our customers operate.

- Ensure the long-term reliability of your equipment.

- Boost production efficiency and reduce operational costs.

- One of our core commitments is to provide readily available spare parts and accessories, significantly extending the life of your plastic production lines.

Shini has dedicated over 55 years to advancing the plastic processing industry