SHINI offers comprehensive solutions for all your plastic processing equipment needs. From material handling to advanced automation, we are here to enhance your production efficiency and quality.

Established in 1991, Varypack is a private enterprise focused on food packaging services and material manufacturing. Shini and Varypack began their collaboration in 2003 and have maintained a strong partnership for over 20 years. In 2022, Shini joined the construction of Varypack’s new production facility in Ningxiang, Hunan Province. The site spans over 30,000 square meters, with a first-phase investment of approximately 170 million RMB. Completed in November 2022 after a 12-month build, the facility now meets intelligent manufacturing standards.

Related Equipment

Integrated System Solution by Shini

As a trusted supplier, Shini equipped the Ningxiang facility with three intelligent systems tailored to Varypack’s production requirements:

1. Gravimetric Dosing and Mixing System

The SGB gravimetric blender enables fully automated, real-time dosing and mixing of various materials with an accuracy of ±0.1%. Its touch-screen interface, combined with a standard Ethernet connection, ensures seamless digital integration and communication, empowering smart factory connectivity in the Industry 4.0 era.

2. Intelligent Centralized Material Handling System

This system incorporates Shini’s proprietary automatic material distribution technology to support unmanned material switching. Aside from periodic refills, the system requires minimal human intervention, significantly enhancing operational reliability. Its advanced digital infrastructure enables full traceability and transparent material flow while seamlessly interfacing with upper-level control systems, helping Varypack build a fully connected data chain.

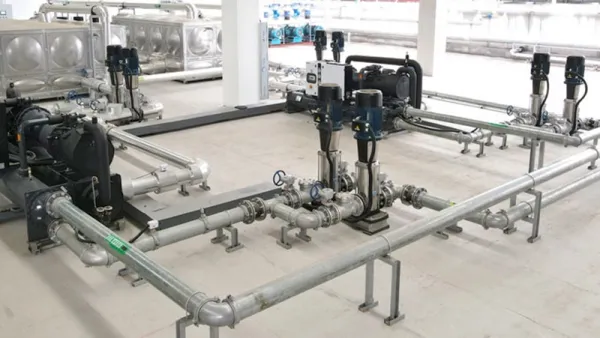

3. Intelligent Central Cooling System

Designed for dynamic production environments, this cooling system supports dual circulation loops for both ambient and chilled water. It automatically adjusts load pressure and water volume based on real-time demand, ensuring optimal operation and energy efficiency. This flexibility guarantees the cooling process precisely aligns with the actual requirements of production equipment.

A company from Shanghai has recently made an additional purchase of over ten ST5 small servo driven robots from Shini for use in the fully automated injection molding of plastic components for cosmetic packaging. This acquisition highlights the company's ongoing commitment to enhancing its manufacturing capabilities and efficiency in the cosmetics sector.

Related Equipment

For the customer, a material handling system was planned that significantly improved production efficiency and reduced the intensity of operations. This initiative not only streamlined the workflow but also optimized the use of resources, enhancing overall productivity.

Related Equipment

Shini has dedicated over 55 years to advancing the plastic processing industry