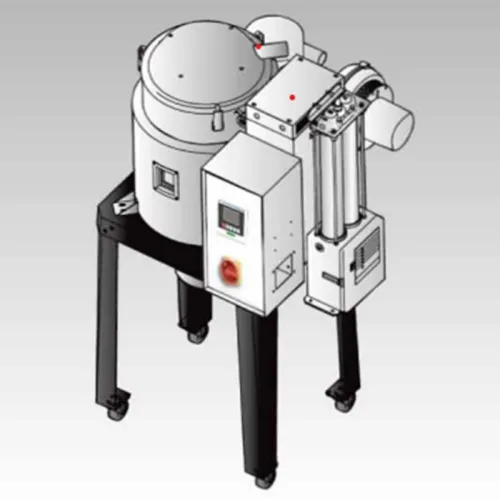

Hopper Dryer

Double layer insulated drying hopper for processing non-hygroscopic plastics

Designed for efficient drying operations, this insulated hopper dryer is ideal for processing most non-hygroscopic plastic materials, ensuring high-quality outcomes in final molded products. Its compact design allows for convenient placement near the feed entrance of molding machines, with options for both floor-standing and mobile installations to accommodate various workspace configurations. For environments with limited ceiling height, the floor-standing installation is particularly beneficial. The insulated hopper dryer also offers a range of optional accessories to cater to specific production needs, such as hot air recycling and magnetic stands.

Designed for efficient drying operations, this insulated hopper dryer is ideal for processing most non-hygroscopic plastic materials, ensuring high-quality outcomes in final molded products. Its compact design allows for convenient placement near the feed entrance of molding machines, with options for both floor-standing and mobile installations to accommodate various workspace configurations. For environments with limited ceiling height, the floor-standing installation is particularly beneficial. The insulated hopper dryer also offers a range of optional accessories to cater to specific production needs, such as hot air recycling and magnetic stands.

- Integrated with a P.I.D. temperature controller, offering precise temperature adjustments and stability, equipped with an LCD status display and RS485 communication interface for streamlined management

- Includes a safety feature that reduces the risk of accidents from overheating, automatically cutting power to prevent damage

- Features an automatic on/off timer for weekly scheduling, enhancing convenience and operational efficiency

- The unique design includes a downward-blowing air bell mouth that disperses hot air evenly, maintaining a stable temperature and increasing drying efficiency

- Larger models, such as the SHD-80U and above, come with see-through doors that allow for easy inspection and cleaning

- Base models up to SHD-450U include an aluminum base that provides durability and stability

- Advanced models from SHD-600U to SHD-750U are fitted with an aluminum magnetic base that enhances installation ease and safety

- The SHD-900U and advanced models are equipped with a manual butterfly valve to fine-tune airflow and enhance drying efficiency

- Double-layer insulation ensures minimal heat loss and consistent temperatures throughout the drying process

- All material contact parts are constructed from stainless steel, preventing contamination and ensuring product purity

| Model | Drying heater (kW) | Blower (kW) | Loading capacity (L) | Dimensions (mm) H×W×D | Floor stand size (mm) H1×W1×D1 | W2 | W3 | Total height (mm) H2 | Height of discharge port (mm) H3 | Air inlet pipe (inch) | Air outlet pipe (inch) | Weight (kg) | |||||||||||

| 2.2 | 0.05 | 20 | 680×575×325 | 790×450×550 | 1260 | 570 | 2 | 1.5 | 40 | ||||||||||||||

| 3 | 0.12 | 40 | 770×770×394 | 790×580×450 | 1300 | 540 | 70 | ||||||||||||||||

| 3.9 | 0.12 | 80 | 940×860×472 | 840×730×560 | 1480 | 550 | 2.5 | 2 | 85 | ||||||||||||||

| 3.9 | 0.12 | 120 | 1190×860×472 | 840×730×560 | 1740 | 100 | |||||||||||||||||

| 6 | 0.12 | 230 | 1470×875×575 | 920×652×795 | 2105 | 570 | 3 | 2.5 | 115 | ||||||||||||||

| 6 | 0.12 | 160 | 1200×875×575 | 920×652×795 | 1825 | 90 | |||||||||||||||||

| 6 | 0.12 | 230 | 1470×875×575 | 920×652×795 | 2105 | 100 | |||||||||||||||||

| 12 | 0.18 | 300 | 1430×1005×695 | 970×790×930 | 2085 | 550 | 130 | ||||||||||||||||

| 12 | 0.18 | 450 | 1840×1005×695 | 970×790×930 | 2435 | 160 | |||||||||||||||||

| 18 | 0.55 | 600 | 1830×1250×915 | 1130×1000×1200 | 2470 | 605 | 4 | 3 | 200 | ||||||||||||||

| 18 | 0.55 | 750 | 2080×1250×915 | 1130×1000×1200 | 2780 | 220 | |||||||||||||||||

| 18 | 0.55 | 900 | 2330×1410×1050 | 2760×1145×1145 | 2765 | 425 | 4 | 4 | 410 | ||||||||||||||

| 24 | 1.1 | 1200 | 2765×1410×1050 | 2990×1145×1145 | 3190 | 560 | |||||||||||||||||

| 32 | 3.7 | 1500 | 3095×1640×1250 | 3470×1340×1340 | 400 | 2000 | 3470 | 360 | 5 | 5 | 685 | ||||||||||||

| 32 | 3.7 | 2000 | 3685×1542×1250 | 3870×1340×1340 | 400 | 2000 | 3870 | 770 | |||||||||||||||

| 58 | 5.5 | 2500 | 3735×1798×1400 | 4000×1482×1482 | 400 | 2260 | 4000 | 295 | 8 | 8 | 800 | ||||||||||||

| 58 | 5.5 | 3000 | 4135×1798×1400 | 4400×1482×1482 | 400 | 2260 | 4400 | 900 | |||||||||||||||

| 64 | 7.5 | 3500 | 4535×1798×1400 | 4800×1482×1482 | 400 | 2260 | 4800 | 1010 | |||||||||||||||

| 64 | 7.5 | 4000 | 4180×2010×1600 | 4550×1680×1680 | 400 | 2460 | 4635 | 405 | 8 | 8 | 1160 | ||||||||||||

| 80 | 11 | 5000 | 4775×2010×1600 | 5150×1680×1680 | 400 | 2530 | 5235 | 390 | 1390 | ||||||||||||||

| 96 | 15 | 6000 | 4520×2250×1800 | 4870×1930×1930 | 400 | 2780 | 4923 | 350 | 153C | ||||||||||||||

| 115 | 18.5 | 7000 | 5460×2250×1800 | 5805×1930×1930 | 400 | 2830 | 5840 | 380 | 1735 | ||||||||||||||

| 128 | 22 | 8000 | 6030×2250×1800 | 5620×1930×1930 | 400 | 2830 | 6425 | 390 | 10 | 10 | 1820 | ||||||||||||

| Flange Installation | |||||||||||||||||||||||

| SHD- | 20U | 40U | 80U 120 | 160U 230U | 300U 450U | 600U 750U | 900U 1200U | 1500U 2000U | 2500U 3000U | 3500U 4000U | 5000U 6000U | 7000 | 8000U | ||||||||||

| ⌀A1 | 231.5 | 231.5 | 254.5 | 254.5 | 254.5 | 254.5 | 254.5 | 254.5 | 254.5 | 254.5 | 254.5 | 254.5 | 254.5 | ||||||||||

| ⌀A2 | 330 | 330 | 330 | 330 | 330 | 330 | 330 | ||||||||||||||||

| ⌀B1 | 140 | 140 | 140 | 210 | 210 | 210 | 210 | 210 | 210 | 210 | 210 | 210 | 210 | ||||||||||

| ⌀B2 | 260 | ||||||||||||||||||||||

| Power: 3φ, 400VAC, 50Hz We reserve the right to change specifications without prior notice. | |||||||||||||||||||||||

With over 55 years of manufacturing experience, we are an experienced manufacturer of plastic auxiliary equipment, now serving clients in more than 80 countries and regions worldwide. Our extensive service network ensures we deliver exceptional support wherever our customers operate.

- Ensure the long-term reliability of your equipment.

- Boost production efficiency and reduce operational costs.

- One of our core commitments is to provide readily available spare parts and accessories, significantly extending the life of your plastic production lines.