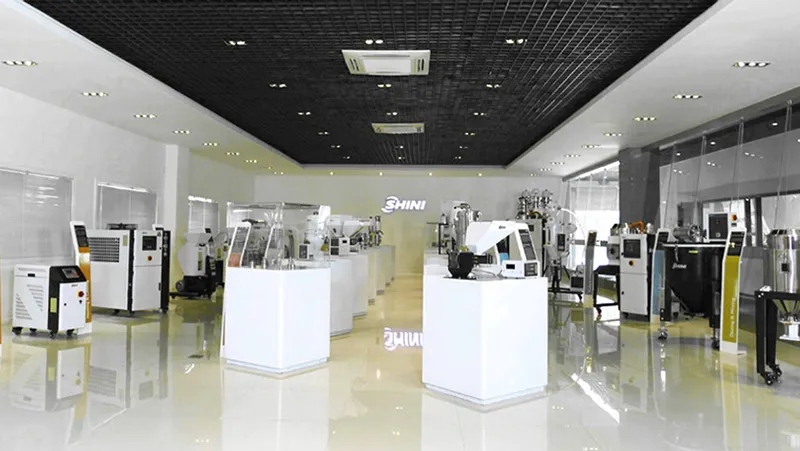

SHINI offers comprehensive solutions for all your plastic processing equipment needs. From material handling to advanced automation, we are here to enhance your production efficiency and quality.

Shini boasts a professional R&D design team, with new product development rigorously managed according to ISO R&D control processes. Each product undergoes thorough market research, solution evaluation, prototype creation, and testing. Only after the prototype passes acceptance testing is it approved for mass production, ensuring new products meet market needs and maintain high quality. Currently, R&D personnel make up 10% of the entire group, guaranteeing dedicated project management from market research to product launch.

Our newly introduced water-soluble 3D printer is used for design modeling and pre-mold sample confirmations. The double-layer screening machine tests granulating efficiency of granulators, and our chiller performance testing lab, with an investment of over 1 million RMB, supports rapid design and development while enhancing product quality.

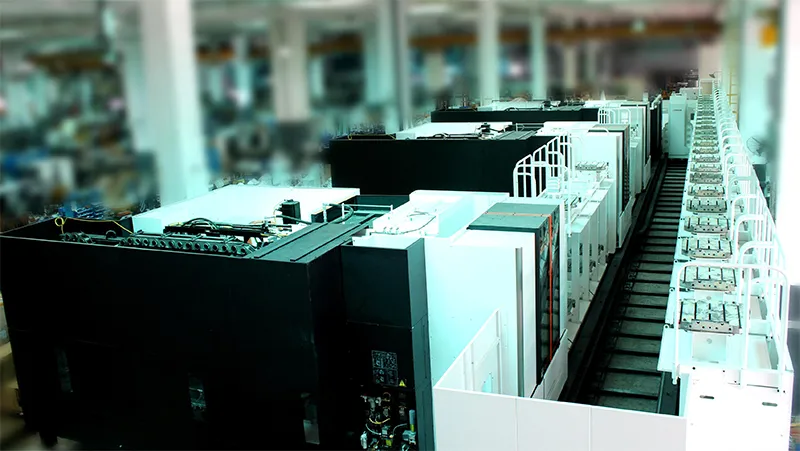

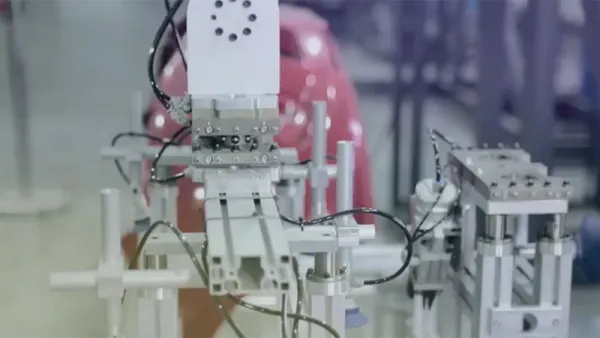

Shini employs cutting-edge technology and advanced equipment in its manufacturing processes. This includes imported CNC machines, shearing machines, hydraulic presses, and laser cutting machines for precise sheet metal processing. High-precision CNC lathes and milling machines are used alongside automated powder coating equipment and various inspection instruments. Leveraging these state-of-the-art tools and exceptional industry expertise, Shini consistently delivers over 60,000 pieces of equipment and 300 system solutions annually, with 70% of the components manufactured in-house.

-

Shini Plastics Technologies, Inc.

Shini Plastics Technologies, Inc. -

Shini Plastics Technologies (Dongguan), Inc.

Shini Plastics Technologies (Dongguan), Inc. -

Shini Plastics Technologies (Foshan), Inc.

Shini Plastics Technologies (Foshan), Inc. -

Shini Plastics Technologies (China), Inc.

Shini Plastics Technologies (China), Inc. -

Shinden Precision Machinery (Chongqing)Inc.

Shinden Precision Machinery (Chongqing)Inc. -

Shini Plastics Technologies (Ningbo), Inc.

Shini Plastics Technologies (Ningbo), Inc. -

Shini India

Shini India -

CONG TY TNHH VSP Vietnam (Shini Vietnam)

CONG TY TNHH VSP Vietnam (Shini Vietnam) -

Shini Germany

Shini Germany

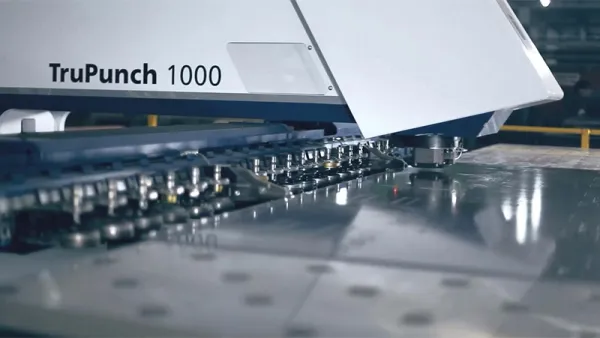

Our facilities are equipped with over 40 high-performance sheet metal processing machines, including laser cutting machines from renowned brands like Trumpf, Han's Laser, Amada, and Bodor. These machines ensure precision in cutting processes. Our CNC bending machines guarantee high-precision sheet metal bending, while CNC punching and spinning equipment meet the stringent demands of advanced sheet metal processing techniques.

Our facilities boast over 50 advanced machining units, including the Yamazaki Mazak horizontal machining center with an FMS flexible production line and the Japanese Okuma five-axis machining center MAC-A5C.

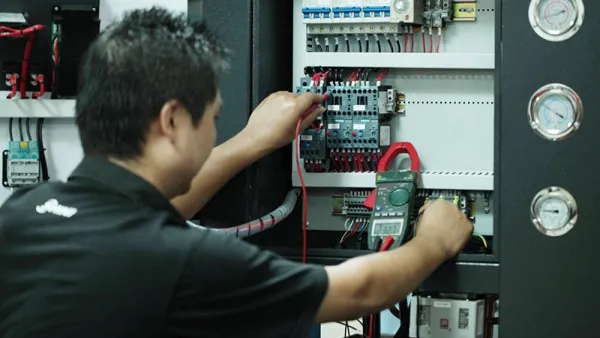

Our factories adhere to the ISO-9001 quality management system, ensuring stringent quality control at every step. We have established dedicated quality laboratories equipped with precision testing instruments and staffed by experienced quality control engineers. Our meticulous approach ensures that from raw materials to final products, each stage is rigorously inspected and controlled.

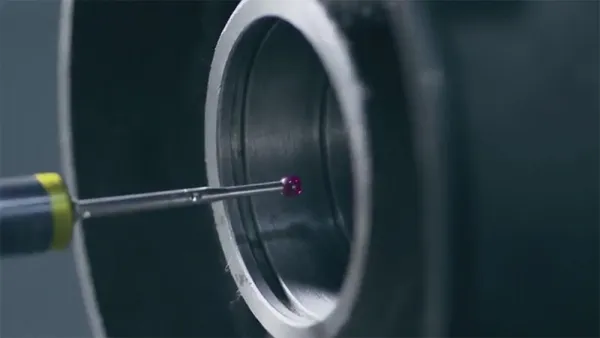

Shini products have received CE certification, and our high standards of quality and service are recognized in international markets. Our testing facilities include high-precision coordinate measuring machines, optical emission spectrometers, vision measuring systems, impact testing machines, salt spray testers, hardness testers, and metallographic microscopes. This comprehensive range of equipment guarantees that every process is under strict quality control. Additionally, our product quality management system allows for tracking and tracing the quality status of products and components, thereby enhancing the efficiency and accuracy of our after-sales service.

Shini has dedicated over 55 years to advancing the plastic processing industry