SHINI offers comprehensive solutions for all your plastic processing equipment needs. From material handling to advanced automation, we are here to enhance your production efficiency and quality.

This company greatly praised the redesigned production system, which has significantly enhanced operations in their injection molding workshop since completion. This update underscores the positive outcomes following the implementation of the updated manufacturing system by Shini, highlighting improvements across the board in efficiency and production capabilities in the solar energy sector.

Related Equipment

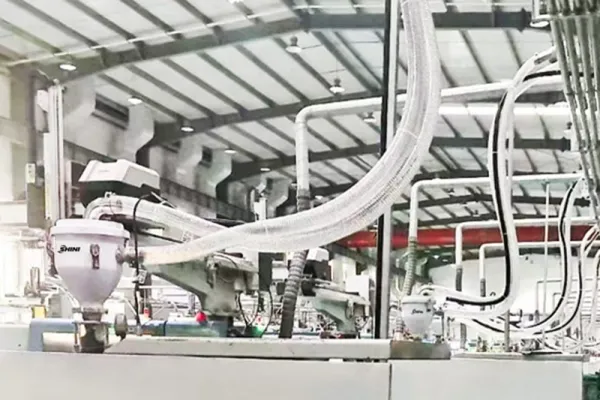

A photovoltaic energy company specializing in solar system materials partnered with Shini to upgrade their raw material processing capabilities. After extensive on-site evaluation and technical consultation, Shini delivered a highly efficient and reliable centralized material handling system tailored to the customer’s process and product characteristics.

Project Background

The client operates 88 injection molding machines (distributed across four rows) with clamping forces ranging from 160 to 260 tons. The materials used include PA, PPO, PPE, and certain fiberglass-reinforced compounds, all used in the production of photovoltaic components.

Solution Features

1. Energy-Saving and Highly Stable System

The system includes four blower sets, each capable of supplying materials to 22 injection molding machines. This centralized setup significantly reduces energy consumption compared to standalone material loaders. To minimize costs and avoid equipment waste, 42 existing single-unit vacuum hopper loaders were integrated into the system by adding diaphragm valves. Additionally, nine SHD-E large-capacity energy-saving dryers were installed in the raw material room. Compared to placing dryers next to each machine, this centralized setup improves ambient temperature and noise levels in the workshop while optimizing space usage.

2. Flexible and Clean Material Distribution

Each dryer is equipped with a multi-pipe shut-off suction box and is connected to a precision-engineered material distribution station. This setup allows seamless switching across multiple channels and pathways with zero material residue, preventing contamination and reducing waste. The distribution station is designed with wear resistance and pipe compatibility in mind, enabling any of the 88 machines to use any material on demand. Up to 32 machines can simultaneously process the same material without disruption.

Client Feedback

Since its implementation, the system has been praised by the client for significantly improving operational efficiency, working conditions, and production consistency. The project has also been positively recognized throughout the photovoltaic energy industry.

Shini has dedicated over 55 years to advancing the plastic processing industry