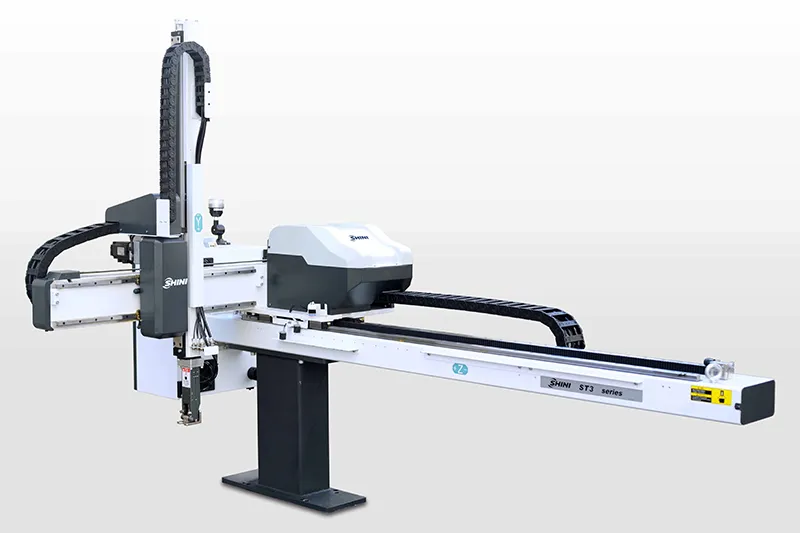

Three-Axis/Five-Axis Servo Driven Robot

Traverse robot used in plastic injection molding process to remove sprues and products

The three-axis and five-axis servo driven robots are engineered for precision and efficiency in the plastic injection molding industry, specifically designed to facilitate the removal of sprues and products during the molding process. They are known for their modular design which simplifies maintenance by allowing quick module replacement instead of full disassembly, enhancing both uptime and cost-effectiveness.

The three-axis and five-axis servo driven robots are engineered for precision and efficiency in the plastic injection molding industry, specifically designed to facilitate the removal of sprues and products during the molding process. They are known for their modular design which simplifies maintenance by allowing quick module replacement instead of full disassembly, enhancing both uptime and cost-effectiveness.

- Utilizes a modular design and card-style assembly structure that makes after-sales maintenance easier by replacing specific modules instead of dismantling the entire machine.

- The drive system operates more stably and possesses superior overload capacity. It also requires only a single regenerative resistor, which saves installation space.

- The main control and servo modules are connected via a unified baseplate, reducing unnecessary wiring and increasing system stability and reliability.

- Servo parameters are set automatically by the control board, eliminating the need for manual driver adjustments.

- Features a bus control interface that is compatible with various types of molding machines (industry standard, European style, Japanese style, etc.) and supports a new 8-inch handheld controller.

- Offers the reliability of a split system while reducing complex wiring steps and decreasing the size of the electrical box.

The three-axis and five-axis servo driven robots are ideal for handling finished products and runners in plastic injection molding processes, supporting a variety of molds such as two-plate, three-plate, and hot runner molds. Capable of performing specialized actions such as arranging, stacking, quality inspection, and embedding, they are suited for injection molding machines with a clamping force of 80 to 300 tons.

| Model ST3- | ||||||

| Robot type | Single kick-stroke beam | Single kick-stroke beam | Frame type beam | Frame type beam | Movable beam | |

| IMM (ton) | 80-160 | 180-300 | 320-450 | 480-650 | 480-650 | |

| Traverse stroke (mm) | 1400 | 1600 | 1800 | 2000 | 2000 | |

| Crosswise stroke (mm) | Main arm | 700 | 900 | 1100 | 1100 | 1000 |

| Sub arm | = | = | = | = | = | |

| Vertical stroke (mm) | Main arm | 800 | 1000 | 1200 | 1300 | 1400 |

| Sub arm | = | = | = | = | = | |

| Max. load (with tool) (kg) | 5 | 5 | 6 | 6 | 10 | |

| Min. pick-out time (sec) | 1.3 | 1.4 | 1.5 | 1.8 | 3 | |

| Min. cycle time (sec) | 5.2 | 5.5 | 6.5 | 6.8 | 13 | |

| Air pressure (bar) | 4-6 | 4-6 | 4-6 | 4-6 | 4-6 | |

| Max. air consumption (Nl/cycle)* | 4 | 4 | 4 | 6 | 6 | |

| Weight (kg) | 250 | 300 | 320 | 340 | 530 | |

| Dimensions (mm) | A | 2060 | 2310 | 2550 | 2750 | 2700 |

| B | 1400 | 1600 | 1900 | 1900 | 1817 | |

| C | 1250 | 1350 | 1450 | 1500 | 1680 | |

| D | 800 | 1000 | 1200 | 1300 | 1400 | |

| E | 800 | 900 | 1160 | 1160 | 1000 | |

| F | 1400 | 1600 | 1800 | 2000 | 2000 | |

| G | 180 | 180 | 250 | 250 | 245 | |

| H | 230 | 230 | 200 | 200 | 145 | |

| I | 1650 | 1900 | 2200 | 2400 | 355 | |

| Notes: "M" stands for middle mold detector (suitable for 3-plate mold) "EM12" stands for Euromap12 communication interface "EM67" stands for Euromap67 communication interface | ||||||

| Model ST5- | ||||||

| Robot type | Single kick-stroke beam | Single kick-stroke beam | Frame type beam | Frame type beam | Frame type beam | |

| IMM (ton) | 80-160 | 180-300 | 320-450 | 480-650 | 660-850 | |

| Traverse stroke (mm) | 1400 | 1600 | 1800 | 2000 | 2200 | |

| Crosswise stroke (mm) | Main arm | 500 | 700 | 850 | 850 | 1050 |

| Sub arm | 500 | 700 | 850 | 850 | 1050 | |

| Vertical stroke (mm) | Main arm | 800 | 1000 | 1200 | 1300 | 1500 |

| Sub arm | 800 | 1000 | 1200 | 1300 | 1500 | |

| Max. load (with tool) (kg) | 5 | 5 | 6 | 6 | 12 | |

| Min. pick-out time (sec) | 1.3 | 1.4 | 1.5 | 1.8 | 2.0 | |

| Min. cycle time (sec) | 5.2 | 5.5 | 6.3 | 6.8 | 12 | |

| Air pressure (bar) | 4~6 | 4~6 | 4~6 | 4~6 | 4~6 | |

| Max. air consumption (Nl/cycle)* | 4 | 4 | 4 | 6 | 6 | |

| Weight (kg) | 290 | 320 | 340 | 360 | 450 | |

| Dimensions (mm) | A | 2060 | 2310 | 2550 | 2750 | 3100 |

| B | 1600 | 1700 | 1900 | 1900 | 2160 | |

| C | 1250 | 1350 | 1450 | 1500 | 1740 | |

| D | 800 | 1000 | 1200 | 1300 | 1500 | |

| E | 800 | 1000 | 1200 | 1300 | 1500 | |

| F | 1400 | 1600 | 1800 | 2000 | 2200 | |

| G | 180 | 180 | 250 | 250 | 230 | |

| H | 110 | 110 | 220 | 220 | 440 | |

| I | 800 | 900 | 1160 | 1160 | 1540 | |

| J | 230 | 230 | 200 | 200 | 245 | |

| K | 220 | 220 200 200 | 245 | |||

| L | 1650 | 1900 2200 2400 | 2620 | |||

| Notes: "M" stands for middle mold detector (suitable for 3-plate mold) "EM12" stands for Euromap12 communication interface "EM67" stands for Euromap67 communication interface | ||||||

With over 55 years of manufacturing experience, we are an experienced manufacturer of plastic auxiliary equipment, now serving clients in more than 80 countries and regions worldwide. Our extensive service network ensures we deliver exceptional support wherever our customers operate.

- Ensure the long-term reliability of your equipment.

- Boost production efficiency and reduce operational costs.

- One of our core commitments is to provide readily available spare parts and accessories, significantly extending the life of your plastic production lines.