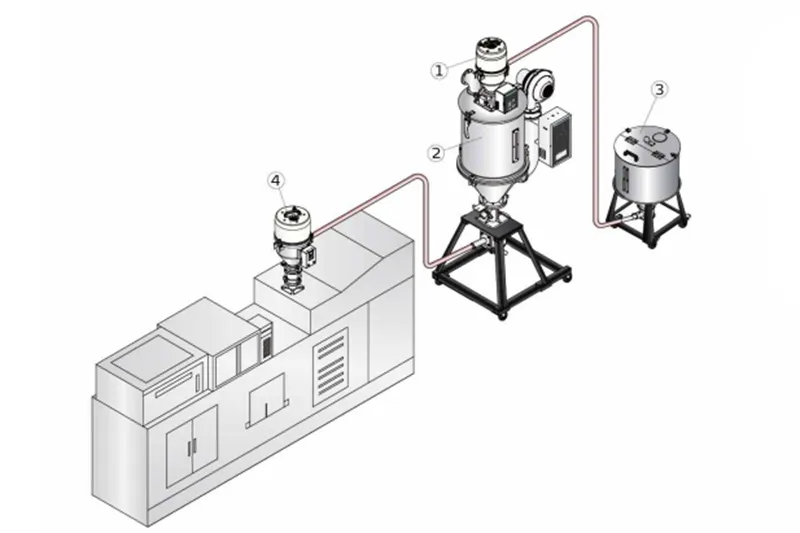

Self-Contained Vacuum Hopper Loader

Plastic feeding machine for conveying plastic pellets, regrind and powders to hopper or processing machine

This self-contained vacuum hopper loader is specifically designed to facilitate the efficient transfer of plastic materials such as pellets, regrind, and powders directly to hoppers or processing machines used in injection molding and extrusion processes.

- Stainless steel hopper ensures durability and contamination-free handling with motor overload protection to safeguard the system.

- Equipped with fabric filters and an automatic cleaning system to maintain purity and streamline maintenance.

- Features manual control switches making it easy to operate, especially when installed at elevated locations.

- Includes an RS485 interface to enhance connectivity and integration with other industrial control systems.

This self-contained vacuum hopper loader is ideally suited for the direct installation on plastic injection molding machines and extrusion machines, or combined with collection hoppers for centralized feeding systems. Once installed, minimal adjustment is required, facilitating continuous and efficient operations.

| Model | |||||

| Blower type | Carbon brush | Carbon brush | Inductive | Inductive | |

| Motor power (kW) | 1.15 | 1.15 | 0.37 | 0.75 | |

| Conveying pipe diameter (inch) | 1.5 | 1.5 | 1.25 | 1.5 | |

| Conveying capacity (kg/hr) | 200 | 300 | 220 | 300 | |

| Hopper capacity (L) | 3 | 6 | 3 | 6 | |

| Material level control | Microswitch | Microswitch | Microswitch | Microswitch | |

| Auto-cleaning function | ● | ● | — | — | |

| Cloth filter | ● | ● | ● | ● | |

| Motor reverse cleaning function | — | — | ● | ● | |

| Dimensions | H(mm) | 610 | 670 | 660 | 735 |

| W(mm) | 345 | 385 | 310 | 350 | |

| D(mm) | 355 | 380 | 430 | 455 | |

| L(mm) | 210 | ||||

| L1(mm) | 180 | ||||

| L2(mm) | 146 | ||||

| Weight (kg) | 13 | 14 | 23 | 26 | |

| Notes: 1) Test conditions of conveying capacity: Plastic material of 0.65kg/L in bulk density and 3-5mm in diameter Vertical conveying height: 4m Horizontal conveying distance: 1m 2) "●" stands for standard, "〇" stands for optional, "—" stands for none 3) Power of SAL-330/360: 1φ, 230VAC, 50Hz 4) Power of SAL-430/460: 3φ, 400VAC, 50Hz | We reserve the right to change specifications without prior notice. | ||||

With over 55 years of manufacturing experience, we are an experienced manufacturer of plastic auxiliary equipment, now serving clients in more than 80 countries and regions worldwide. Our extensive service network ensures we deliver exceptional support wherever our customers operate.

- Ensure the long-term reliability of your equipment.

- Boost production efficiency and reduce operational costs.

- One of our core commitments is to provide readily available spare parts and accessories, significantly extending the life of your plastic production lines.