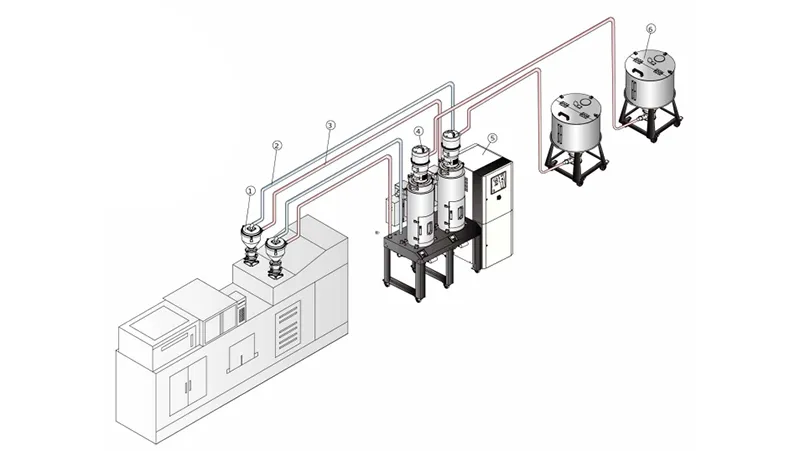

Honeycomb All-in-One Compact Dryer

Plastic processing machine combining functions of dehumidifying, drying and conveying

This honeycomb all-in-one compact dryer is an innovative dryer integrating three main functions: dehumidifying, drying, and conveying. Designed to optimize the handling of hygroscopic plastic materials such as PET, PA, and PC. Its main features are tailored to enhance the efficiency and quality of plastic processing.

- Combines dehumidification, drying, and conveying capabilities, streamlining the plastic processing workflow

- Utilizes a full molecular sieve honeycomb rotor that provides stable, low dew point air, preventing material contamination that can occur with older dual-tower systems

- Features a cutting system within the suction box to ensure that no residual materials remain in the tubes, preventing moisture regain

- The insulated drying hopper uses a downward-blowing air pipe design coupled with a cyclone exhaust system to minimize heat loss and improve drying efficiency

- Equipped with two drying hoppers, each with individually controlled drying temperatures, allowing for simultaneous dehumidification and drying of two different types of plastics, typically used with dual-color molding machines

- Includes a weekly timer for scheduling automatic operations, enhancing productivity with minimal supervision

- The new and improved drying hoppers reduce floor space requirements by 14-20% compared to previous models

As an important piece of plastic auxiliary machinery, this honeycomb all-in-one compact dryer is specifically designed for plastics that are susceptible to moisture, providing essential dehumidification, drying, and conveying operations. For volatile materials, it is recommended to use an EOF oil filter to ensure safe and effective processing.

| Model SCD- | |||||||||||||

| Drying system | Drying heater power (kW) | 3 | 3 | 4 | 6 | 4 | 4 | 4 | 4 | 6 | 6 | 12 | 12 |

| Drying blower power (kW) | 0.4 | 0.4 | 0.4 | 0.75 | 0.18 | 0.18 | 0.75 | 0.75 | 0.75 | 0.75 | 1.5 | 1.5 | |

| Insulated hopper capacity (L) | 20 | 40 | 80 | 120 | 40 | 80 | 120 | 160 | 160 | 230 | 300 | 450 | |

| Dehumidifying system | Regeneration heater power (kW) | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 4 | 4 | 4 | 4 |

| Regeneration blower power (kW) | 0.4 | 0.4 | 0.4 | 0.4 | 0.12 | 0.12 | 0.18 | 0.18 | 0.18 | 0.18 | 0.4 | 0.4 | |

| Dehumidifying air volume (m³/hr) | 30 | 30 | 50 | 80 | 40 | 40 | 80 | 80 | 120 | 120 | 200 | 200 | |

| Feeding system | Feeding blower power (kW) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Diameter of material pipe (inch) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | |

| SVH-L hopper (L) | 3* | 3* | 3* | 3* | 3 | 6 | 6 | 6 | 6 | 12 | 12 | 12 | |

| SHR-U hopper (L) | 3 | 3 | 6 | 6 | 3 | 6 | 6 | 6 | 6 | 12 | 12 | 12 | |

| Dimensions | W(mm) | 1081 | 1097 | 1159 | 1159 | 1081 | 1097 | 1159 | 1159 | 1159 | 1257 | 1460 | 1460 |

| D(mm) | 900 | 900 | 1000 | 1000 | 903 | 903 | 903 | 903 | 903 | 903 | 1020 | 1020 | |

| H(mm) | 1400 | 1500 | 1670 | 1710 | 1685 | 1771 | 1957 | 2102 | 2102 | 2014 | 2160 | 2350 | |

| Weight (kg) | 235 | 280 | 330 | 385 | 295 | 325 | 340 | 350 | 390 | 420 | 565 | 595 | |

| Model SCD- | |||||||||||

| Drying system | Drying heater power (kW) | 18 | 18 | 24 | 24 | 3×2 | 3.9×2 | 3.9×2 | 6×2 | ||

| Drying blower power (kW) | 3.75 | 3.75 | 7.5 | 7.5 | 0.75 | 0.4 | 0.75 | 1.5 | |||

| Insulated hopper capacity (L) | 600 | 750 | 900 | 1200 | 40×2 | 80×2 | 120×2 | 160×2 | |||

| Dehumidifying system | Regeneration heater power (kW) | 7.2 | 7.2 | 10 | 10 | 3 | 3 | 4 | 4 | ||

| Regeneration blower power (kW) | 0.75 | 0.75 | 1.5 | 1.5 | 0.4 | 0.4 | 0.4 | 0.4 | |||

| Dehumidifying air volume (m³/hr) | 400 | 400 | 700 | 700 | 80 | 80 | 120 | 200 | |||

| Feeding system | Feeding blower power (kW) | 1.5 | 1.8 | 3.75 | 3.75 | 1.5 | 1.5 | 1.5 | 1.5 | ||

| Diameter of material pipe (inch) | 1.5 | 1.5 | 2 | 2 | 1.5 | 1.5 | 1.5 | 1.5 | |||

| SVH-L hopper (L) | 12 | 12 | 24 | 24 | 6 | 6 | 6 | 6 | |||

| SHR-U hopper (L) | 12 | 12 | 24 | 24 | 3 | 6 | 6 | 6 | |||

| Dimensions | H(mm) | 2380 | 2610 | 2640 | 3070 | 1655 | 1866 | 1800 | 2113 | ||

| W(mm) | 1745 | 1745 | 2140 | 2140 | 1422 | 1886 | 2084 | 2124 | |||

| D(mm) | 1255 | 1255 | 1380 | 1380 | 853 | 915 | 915 | 930 | |||

| Weight (kg) | 640 | 690 | 850 | 900 | 320 | 400 | 500 | 565 | |||

| Notes: 1) Plastic materials can be fully dried by drying air with dew-point temperature ≤-20°C 2) "*" stands for hopper receiver SHR-CP-U 3) Power: 3φ, 400VAC, 50Hz | We reserve the right to change specifications without prior notice. | ||||||||||

With over 55 years of manufacturing experience, we are an experienced manufacturer of plastic auxiliary equipment, now serving clients in more than 80 countries and regions worldwide. Our extensive service network ensures we deliver exceptional support wherever our customers operate.

- Ensure the long-term reliability of your equipment.

- Boost production efficiency and reduce operational costs.

- One of our core commitments is to provide readily available spare parts and accessories, significantly extending the life of your plastic production lines.